Home › INSTALLATION › INSTALLATION MANUAL › Coastal Installs

Installing Polymeric Cladding and Soffit in Coastal Areas

Current codes regulate coastal areas and place stringent performance requirements on cladding installed in these areas. Polymeric claddings are a great choice. They offer beauty and stand up to more extreme coastal conditions. Use these quick tips for installing polymeric cladding and soffit in coastal regions.

Understanding the Use of Polymeric Cladding and Soffit in High-wind Regions

These updates will help you stay compliant and achieve the highest performance in coastal regions:

- The design pressure rating reflects the highest wind application for which the cladding is suitable and allows building code officials in high-wind regions to determine the appropriate cladding and soffit to install.

- Vinyl siding, insulated vinyl siding and polypropylene siding products have a wind design pressure rating published as part of the product certification program.

- Vinyl soffit in high wind regions needs to exhibit a proper design pressure rating.

- Vinyl siding and insulated vinyl siding products designed for use in high-wind regions typically have reinforced nail hems (i.e., double or rolled-over nail hems versus single-nail hems).

- Polypropylene siding in high-wind regions typically needs to be installed 8" to 10" on center based on manufacturer’s installation instructions.

Installation Tips

Installing the Starter Strip

- In normal wall applications, starter strips are required.

- Vinyl siding, insulated vinyl siding and polypropylene siding starter strips are unique and may not be used interchangeably so follow manufacturer specifications for each product category.

- A starter strip not matched to the lock design of the cladding could cause the bottom course to blow off, which can lead to product failure.

- Do not use J-channel or other types of trim in place of a starter strip except when installing vertical siding.

Cladding Under Windows at the Top of Wall

- Failure to use proper connection can create a weak point for the system.

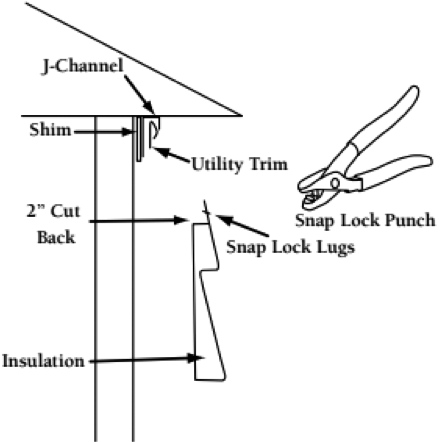

- Use of utility trim and punch-locked vinyl siding or insulated vinyl siding is critical under windows and at the top of the walls.

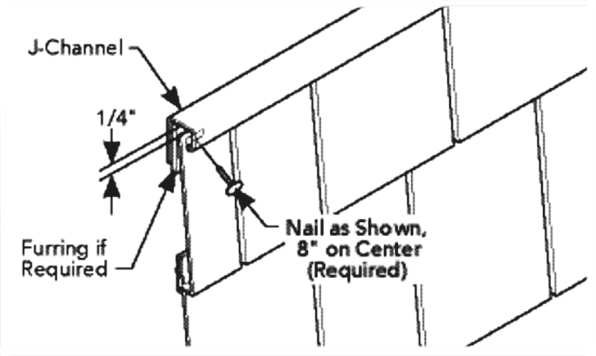

- Using a snap lock punch (or other nail hole-creating tools), punch every 6" along the cut edge of vinyl siding and insulated vinyl siding and every 8" along the cut edge of polypropylene siding.

- Any time the top lock has been removed from cladding, utility trim should be used as a receiver to secure the punched-tab cladding panel.

- Furring may be required.

Polypropylene Siding

Insulated Vinyl Siding

Finishing

Soffit Installation Tips

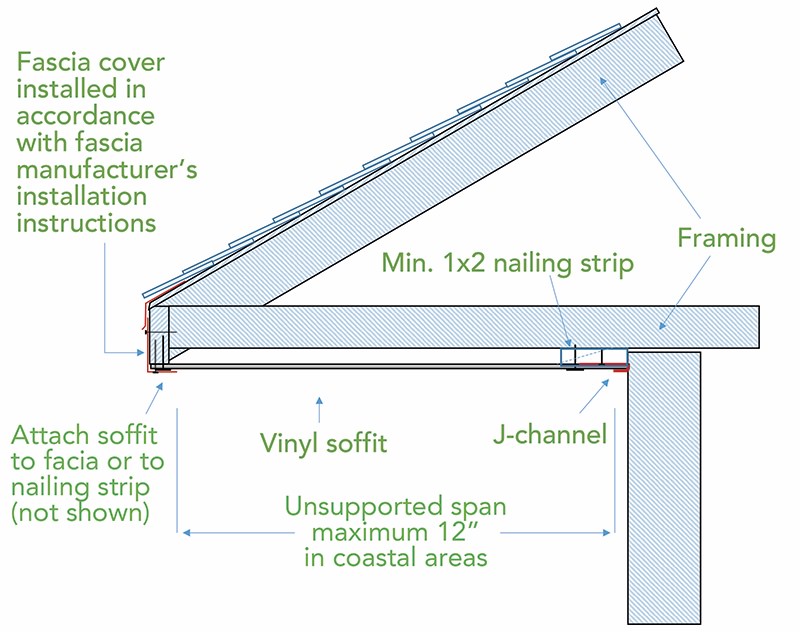

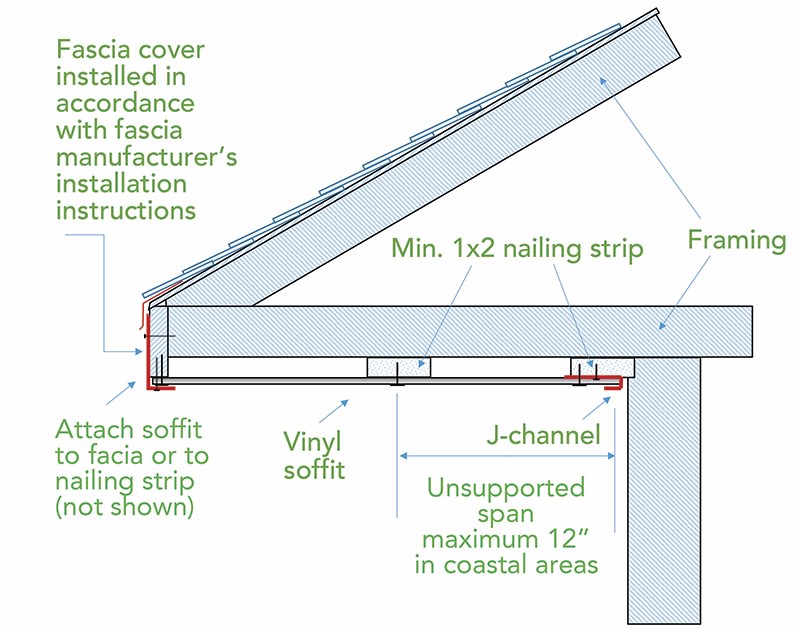

- Vinyl soffit must be fastened at both the fascia and wall.

- In high wind regions, where the unsupported span of soffit panels is greater than 12", intermediate nailing strips shall be provided.

- Once vinyl soffit is installed, fascia covers can be installed into utility trim or behind the existing drip edge.

- Always pre-drill holes into fascia and do not nail tight.

Multi Span Soffit Installation

Single Span Soffit Installation

Installation and Maintenance

Vinyl Siding Installation Manual

Basic guidelines for vinyl siding installation. (Spanish version and French version also available)

Read More